Vibration analysis

The main goal of the practical part was to perform a modal analysis calculation. This analysis is the first step to determine the basic dynamic characteristics such as oscillation, with its main factors being eigenshapes and eigenfrequencies. This analysis also evaluated the effect of preloading the screws.

Modifying the model and simulation settings

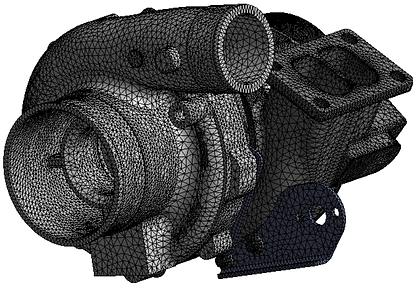

In the initial phase, it was necessary to modify the geometric model. Due to computing power constraints, it was necessary to simplify some parts of the model, for example by removing the recesses or chamfers for the screws.

Subsequently, the input and boundary conditions of the simulation were defined, which represent a key element for the correctness of the resulting analysis. At the same time, it was necessary to assign the corresponding materials to the different parts of the turbocharger. Cast aluminium was used for the compressor casing and disc, while the turbine and bearing housings were made of stainless steel. The bypass valve mounting plates and compressor connection plates were made of structural steel, while the bolts were made of carbon steel. These steps were necessary to accurately set up the simulation and ensure reliable results

Computational approach

As the turbocharger consists of several parts, it was crucial to set up the contacts between them correctly. The choice of approach to this problem significantly affects the computational complexity and accuracy of the simulation.

One option is to consider the turbocharger as a single unit (see figure on the left), which means setting fixed connections on the entire contact surfaces. This approach reduces the computational complexity and shortens the computation time. However, the disadvantage is the increased stiffness of the whole model, which can lead to less accurate results.

A more accurate method, which was chosen for this modal analysis (see figure on the right), is to break the turbocharger down into individual parts with detailed contact definitions. The first step was to set up the contacts between the parts. This was followed by a precise adjustment of the bolt preload, which is necessary for a realistic simulation of the mechanical behaviour. This procedure allows for more accurate results, although it requires more computing power and longer processing time.

Boundary conditions

In the next stage, it was necessary to define the boundary conditions. As a fixed support, the surface of the turbine casing was set to ensure the attachment of the turbocharger to the leads or directly to the engine.

The model was then discretised, generating approximately 950,000 nodes and 550,000 elements. The structural analysis was then calculated. This analysis took into account the effect of the bolt preload, which causes deformation and friction between the parts. The result was information on the areas where the parts are firmly connected.

A modal analysis was then performed based on the structural analysis. The aim was to determine whether the natural frequency of the structure was within the working frequency spectrum, which in this case was from 0 Hz to 335 Hz. This range corresponds to the ignition frequencies of the car engine.

The results

The output of the performed modal analyzes was the determination of the first six natural frequencies, as was previously set for both approaches.

For the first natural frequency, a difference of approximately 7% was shown between the two approaches. It was crucial, however, that the first natural frequency did not lie in the defined spectrum of working frequencies. This result therefore confirms that the turbocharger was designed to avoid resonances caused by the engine's firing frequency.